Interstate High Speed Rail Taxonomy

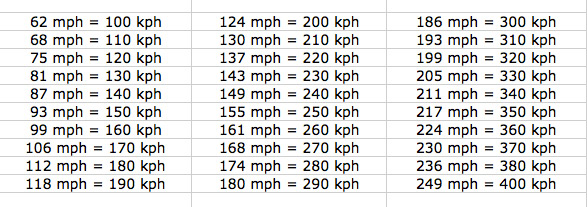

Interstate High Speed Rail Taxonomy is organized by speed categories from slowest to fastest. Outside America, others would call it an Intercity High Speed Rail Taxonomy. Other advanced and emerging nations have better Intercity Passenger Rail than America, so this narrative series often lists miles per hour (mph) beside kilometers per hour (kph). Note: 6.213 mph = 10 kph and most nations denominate passenger rail speeds by increments of 10 kph (150. Since there are plenty of exceptions worldwide, I’ll often use the word “typically” as a descriptor. — Thomas Dorsey, Soul Of America

Mph-to-Kph Conversion Table for Passenger Rail

If you’re an American planning to visit Western Europe or Eastern Asia, please include a High-Speed Rail (HSR) ride between two cities. Along with urban and rural scenery, you will appreciate the speed, frequency, reliability, and comfort features named below. Afterward, imagine how an Interstate HSR System would benefit you at home.

If that sales pitch doesn’t work for you, watch this short video about French HSR.

Slower Intercity Passenger Rail Routes

In America, Legacy Rail routes for passengers support 30-80 mph (65-128 kph) Top Speed: Diesel-engine trains run on them; their infrastructure consists of old bridges & tunnels, level crossings between railway & roadway, old track switches, old electric power, signaling & communication systems). Most have sharp curves, and 1-track tunnels, followed by alternating sections of 1 or 2 main tracks shared by freight, commuter, and sometimes, long-distance passenger trains. Due to long stopping distances, freight trains rarely exceed 60 mph on them.

In many urban areas, commuter trains share tracks with freight trains. A 3, 4, 5, or 6-cabin commuter train typically has 180, 240, 300, or 360 passengers capacity. Commuter trains typically run every 45-60 minutes at Peak Hours and every 2-3 hours Off-Peak.

Amtrak Long-Distance trains are also licensed to run on a number of routes owned by Freight Rail companies and Commuter Rail agencies. An 8 to 9-cabin Long-Distance train typically has 290-320 passenger capacity due to the space-consuming need for sleeping quarters, luggage, more restrooms, and a cafe car. Commuter and Long-Distance trains both require taxpayer subsidies to operate.

In America, Intercity Passenger Trains are operated by Amtrak, one private company called Brightline, and a few scenic railway companies out West. Amtrak features three types of service: (1) Northeast Corridor High-Speed Trains, (2) Regional Trains, and (3) Long-Distance Trains. Brightline features Regional trains in Florida and plans to break ground on a High-Speed Train service between Las Vegas and Southern California.

Excluding California HSR and Brightline West HSR, all Intercity Passenger trains, Commuter trains, and Freight trains will mostly run on Legacy Rail routes.

In America and Rest-of-World, Commuter Rail Routes support 80-93 mph (128-150 kph) Top Speed: Diesel-engine freight trains and Diesel-Electric engine commuter trains run on them. Since diesel-electric locomotives use battery power while in stations and emit lower air pollutants, they are gradually replacing diesel engines worldwide. In America, Federal Railroad Administration rules limit track speeds to 80 mph over standard-gated railroad crossings and to 95 mph over railroad crossings enhanced with four-quadrant gate systems that include vehicle detection on tracks. These are called Quad Gate Systems.

Many of these routes have 2-track tunnels to match 2 Main Tracks plus intermittent Siding Track for freight trains to pull aside. A few routes have over/underpasses at railroad crossings. Though diesel-electric trains can reach 125 mph (201 kph), they rarely exceed 80-81 mph without more over/underpasses because a diesel-electric locomotive pulling an 8-car passenger train on level track needs about 1 mile to stop. That is why routes having Quad Gate Systems still limit diesel-electric trains to 95 mph.

For shorter braking distances, most Commuter trains in America run only 5 or 6 cabins (300-360 passengers capacity); Commuter trains typically run only 6-10 daily roundtrips between suburbs and Central Business Districts.

Faster Intercity Passenger Rail Routes

Regional Rail Routes typically support 93-125 mph (150-201 kph) Top Speed: They are upgraded from Commuter Rail Routes. When they are upgraded to support electric trains, the trains have pantographs that contact overhead wires, called “catenary”. In that manner, pantographs draw high voltage from catenary to power train locomotion.

Siemens and others now make Electro-Diesel (Dual-Mode) locomotives that operate as diesel + battery power when there is no catenary, then raise pantographs to draw electricity when catenary are present. These trains run in low-emission diesel-mode in low-traffic rural corridors that lead to large urban areas having electric rail infrastructure (electric substations & catenary). Such trains are said to eliminate 90-95% of Smog and GHG emissions compared to diesel-only trains. Electro-Diesel locomotive trains don’t accelerate & brake as fast as lighter weight Electric locomotion trains, but they give states and regions many years to build out electric rail infrastructure.

Electric trains weigh less than diesel and diesel-electric trains for faster acceleration and shorter braking distances.

Electric Regional Rail Routes typically have more street closures, 2 Main Tracks for passenger trains, and a 3rd Main Track (see diagram below) or intermittent Siding Track for freight trains. They also have modern track switches, modern signaling systems, and Quad Gate Systems or other upgraded gating at railroad crossings. When they have complete railroad over/underpasses in urban areas, Electric Regional Rail Routes enable electric trains to achieve 106-112 mph (170-180 kph) around the world and 110 mph in America.

Regional Trains running on Regional Rail Routes typically operate every 15-60 minutes at Peak Hours and every 45-90 minutes Off-Peak — both depending on ridership demand.

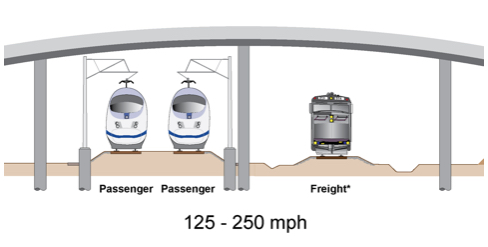

HSR or Regional Rail separated from Freight Rail; credit High Speed Rail Alliance

High-Speed Rail (HSR) infrastructure is required for High-Speed Train (HST) to operate at top speeds. An HSR route’s Top Speed is largely certified by the degree of rail curvature called “Minimum Curve Radii”, the degree of rail slope called “Gradient”, and the elimination of all level railroad crossings. To achieve straighter & flatter routes, substantial earthmoving, tunnels, and/or viaducts are required. To achieve smoother rides, continuous-welded rail, concrete rail ties, and precise track-shaving are required. Dedicated tracks and advanced signaling are required for frequent service of Intercity Passenger Trains.

HSR systems require dependable electric grids feeding electric substations along their route. The highest voltage (kilovolts or “kV”) is supplied in a nation’s Hertz frequency of Alternating Current (AC). Most countries supply AC at 50 Hertz frequency. America, Canada, Mexico, Japan, South Korea, Taiwan, Brazil, and Saudi Arabia supply AC at 60 Hertz frequency.

At the risk of over-simplifying electric engineering terms, early HSR routes supplied 1.5 kV, 6.25 kV, 12 kV, 12.5 kV, 15 kV, or 20 kV AC to electric trains. A few HSR routes supplied 3 kV Direct Current (DC). Over time passenger train companies or agencies discovered that 25 kV AC and tighter strung catenary are optimal to power High-Speed Trains. As more nations upgrade to HSR systems, the emerging standard has become 25 kV AC for speeds over 124 mph (200 kph).

Advanced signaling and automated train control systems assist HST conductors because speeds above 124 mph are too fast for human reaction time alone.

For higher speed, safety, and schedule reliability, HSR systems build over/underpasses at all railroad crossings, close off small streets, and install fencing to prevent people, animals, and automobiles from crossing. These routes are designed to operate above financial breakeven.

1st Generation HSR Routes can typically support 124-130-137-143 mph (200-210-220-230 kph) Top Speeds: Their electric rail infrastructure is upgraded to remove bad curves; mostly electric trains run on them for faster acceleration & deceleration; they have upgraded signaling, advanced train control & communication systems; a 5-cabin High-Speed Train conveys about 250 passengers; HST typically runs every 30-45 minutes at Peak Hours, every 60-90 minutes Off-peak on them; A small percentage of these routes permit 125 mph diesel-electric locomotives until the route converts to electric power systems; they typcially feature 12 kV, 12.5 kV, or 15 kV AC electric power; many of these routes HST typically run at 86-90% schedule dependability on these routes.

2nd Generation HSR Routes can typically support 155-162-168-174 mph (250-280 kph) Top Speeds: Their electric rail infrastructure is upgraded with many new segments to be straighter & flatter than 1st Generation HSR; aerodynamic HST use their dedicated high-speed tracks; they have milder curves, more tunnels & viaducts, faster track switches; they feature 25 kV AC, modern signaling, automated train control & communication systems; HST typically run 155-174 mph (250-280 kph) on them; a typical 6 to 7-cabin HST has 300-350 passenger capacity; they typically run every 20 minutes at Peak Hours, every 40 minutes Off-peak at 93-96% schedule dependability.

3rd Generation HSR Routes typically support 186-192-199 mph (300-310-320 kph) Top Speeds: Their rail infrastructure is electrified and designed straighter & flatter than 2nd Generation HSR Routes; their tracks are shaved for smooth rides and dedicated to light-weight, aerodynamic HST; a typical 8 to 12-cabin train has 360-600 passenger capacity, while 8 to 12 single-level or bi-level cabin trains enable 570-900 passenger capacity; HST typically runs every 15 minutes at Peak Hours, every 30 minutes Off-peak at 97-98% schedule dependability on them. Japanese HST is an exception with 16-cabin trains having 1,323 passenger capacity, running every 5-10 minutes at Peak Hours and every 15-20 minutes Off-peak with 99.9% schedule reliability.

LGV Southeast in France is 4th Generation HSR Route, opened 2017; source Wiki

4th Generation HSR Routes are designed to support 205-249 mph (330-400 kph) Top Speed: Their nextgen infrastructure is designed to be straighter, flatter & smoother shaved than 3rd Generation HSR Routes; their overhead catenary is strung tighter and more durable than 3rd Generation HSR Routes; some Nextgen HST run 205-217 mph (330-350 kph) on them; these routes are designed for 97-99.9% schedule dependability; a typical 9-11-cabin train has 500-600 passenger capacity, while 9 to 11 bi-level cabin trains enable 740-855 passenger capacity; these routes set safety standards for all mass transportation modes.

In the rest of this series, I combine all generations of High-Speed Rail routes together as “HSR” for group context but separate HSR generations when specificity requires. “HSR systems” refer to the combination of HSR route infrastructure, HST, and high-speed operating practices.

Regional Trains & High Speed Trains

Japan, France, United Kingdom, Germany, Italy and America invested modest R&D sums on electric-powered commuter & intercity trains to reach 81-93 mph (130-150 kph) after World War II. But once Japan introduced the first 130 mph (210 kph) HSR system in 1964, other advanced nations coveted its speed, capacity, frequency, schedule reliability, and safety.

The French took passenger train & railway engineering to another level by building the fastest HST in 1981 (168 mph), 1988 (186 mph), and 2007 (199 mph) while maintaining a spotless safety record in commercial operation. At the same time, Italians introduced wheel technology that tilts HST with the advanced suspension to enable 12 mph (20 kph) faster speeds through curves.

Later, Germany mastered the system integration of Regional Trains & HST in weblike, high-frequency networks.

While Japan perfected electric power to every unit of the train (called “EMU” for Electric Multi-Unit), France perfected electric locomotives in the front and rear of passenger cabins. Railway engineers debate which locomotion approach is best overall.

A Law of Physics is that wind drag scales as the cube of vehicle speed. That means an HST that requires 1X electricity to overcome wind drag at 150 mph, requires 2X electricity at 225 mph, and 4X electricity at 300 mph.

That Law of Physics has driven Nextgen HST Builders to construct lighter-weight trains and regenerative brakes that create electricity for on-board heating, ventilation & air conditioning. Small gaps between cabins and uneven cabin heights increase wind drag for train vibration, noise, and energy consumption. Nextgen HST has small inter-cabin gaps and even cabin heights for aerodynamic contours. Depending on the train builder, Nextgen HST can run at 199 mph while consuming 20-22% less energy than Current HST at the same speed.

Some HST Operators already benefit from utility companies adding cheaper wind, solar and geothermal energy to electric grids. Many HSR Builders are also lowering energy costs by upgrading circuitry in electric substations along routes. Those combined advancements have enabled HST Builders to certify that Nextgen HST can safely operate at 236-249 mph (380-400 kph) on 4th Generation HSR.

In 2017, China was the first nation to introduce Nextgen HST running 217 mph (350 kph) on a 4th Generation HSR Route. An equally remarkable engineering feat is that you can balance a coin on the train’s window sill at 217 mph. Other HST Operators have announced 2024-30 plans to introduce Nextgen HST running at 205, 211, 217, 220, or 224 mph (330, 340, 350, 355, 360 kph) on 4th Generation HSR routes. At present, no HST Operator plans to run HST higher than 224 mph at higher energy costs and higher maintenance costs from wearing down wheels and brakes faster.

Speed isn’t the only attraction for HST passengers. Excluding some Asian countries where HST have 5 narrow seats across a row in Coach Class, most HST has 4 comfortable seats across a row in Coach & Business Class, large windows, window shades, better seat lamps, better WiFi, electric outlets & tray tables at each seat, well-stocked cafe cabins, larger restrooms, and more wheelchair accessibility than Regional trains.

Italian HST Operators took passenger amenities to another level. They introduced First Class service that has premium leather reclining seats, 3 or 2 seats across a row, private group seating, Quiet-Cabins and the option for upscale dining.

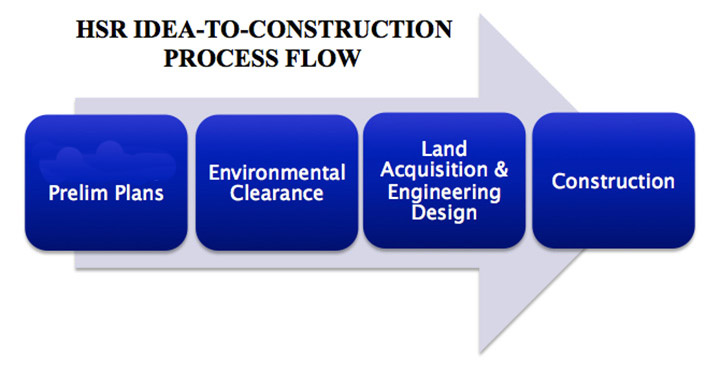

HSR & Regional Rail Feasibility Idea to Construction Process

After Feasibility is approved by state DOT officials and governors, our HSR-Regional rail Preliminary Plans typically require 30% Engineering Design with renderings for initial public input and 1-3 route alignments, stations, and trains. It’s followed by 18-24 months to select the route for Environmental Review with more formal public input. The selected route must often overcome NIMBY lawsuit(s) to reach Environmental Clearance.

Occasionally, non-contested Rights-of-Way (Land) Acquisitions occur simultaneously with the Preliminary Plan and Environmental Review. Afterward, the entire Rights-of-Way Acquisition and 100% Engineering Design commence over 12-24 months per funded segment. Then, Construction takes about 4 years per funded segment.

HSR Idea-to-Construction Process Flow; Land Acquisition is for rights-of-way and stations

After the corridor receives Preliminary Plan funding, it takes 4-6 years to enter Construction. For example, the California HSR mega-project took 6 years from the voter-approved state bond measure to enter Construction. Consequently, USDOT should prioritize funding to 3 public HSR projects where active construction needs acceleration OR large project segments that have completed Preliminary Plans and have acquired substantial rights-of-way.